Heritage

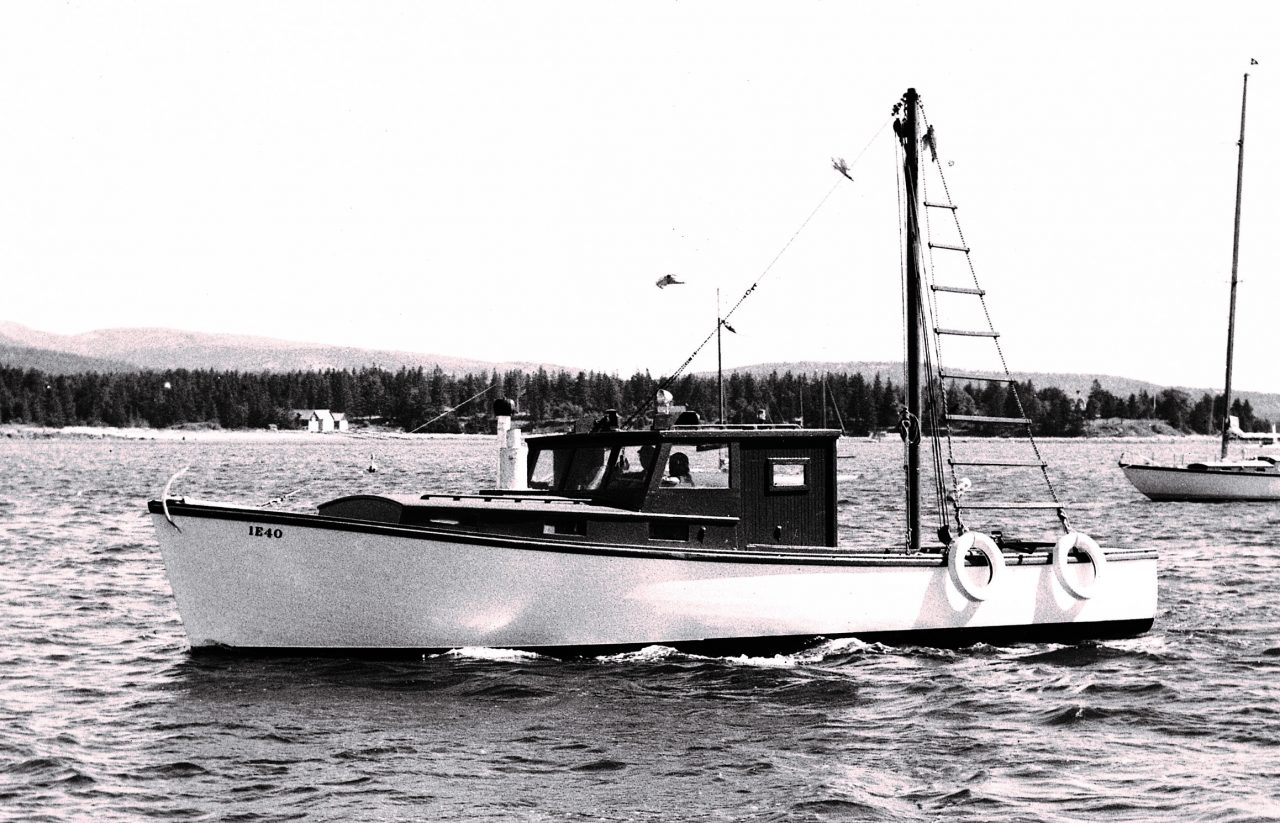

The Hinckley Company started in 1928 as the Manset Boatyard in Southwest Harbor, Maine. Henry R. Hinckley’s focus was on servicing the local lobster boats as well as the yachts of summer residents on Mt. Desert Island. In 1933, Henry built his first boat, Ruthyeolyn, a 36-foot fisherman with beautiful lines that are surprisingly familiar and still look the part even today.

That first boat was fished hard for 9 months of the year and then varnished up and chartered in the summer months to vacationers. From the very beginning, the yachts from the Hinckley yard were kept to the highest standards. Henry was not satisfied with many off-the-shelf parts and soon the yachts from Hinckley came to feature custom designed and fabricated hardware such as stanchions, chocks, pulpits and masts. This attention to detail made these yachts distinctive and, in time, they would earn the collective admiration of sailors and yachtsmen around the world.

There was something in the way they moved through the water — stately, proud and elegant — or swung on their pennants in the harbor at dusk. People who knew boats could instantly spot a Hinckley; those who didn’t were simply able to appreciate the graceful lines and the glistening brightwork.

Beautiful, Functional Design

The lines of a Hinckley were a direct result of their need to endure the rigors of life among the rocky coves and jutting promontories of Maine’s Acadian coast. Then as now, frivolous design had no place on such unforgiving waters. A specific form was borne of these nautical circumstances, characterized by a strong, well-found hull, sweeping deck lines to quickly shed foaming waters, with overhanging bows and fine counters to lend stability in angry seas.

Their speed and stamina were a direct result of Henry’s training and his background studying aeronautical and mechanical engineering at Cornell. Henry insisted on making his boats light yet strong and was never afraid to innovate. In the 1950s, for instance, Hinckley was one of the first to forego traditional oak frames and planking in favor of fiberglass — according to the pundits, completely unsuited to the construction of a “proper” yacht. But Hinckley saw in fiberglass what the traditionalists had missed — an opportunity to save weight while adding strength. And without sacrificing the aesthetic beauty for which Hinckleys were known. This same thinking led to the use of carbon and Kevlar from bow to stern in our Picnic Boats and Motor Yachts 25 years ago.

Composites and Innovation

Today, Hinckley remains one of the few recreational builders using Carbon composites from bow to stern vacuum-infused with epoxy for incredible strength. We were one of the first American builders to adopt SCRIMP resin infusion and today we remain a world leader. Our single bond infusion allows for an integrated, chemical bond between hull and support structure. With our move to epoxy resin infusion in 2018, we are now building with a resin material of 40% greater strength and improved environmental benefits. We believe so strongly in this approach that we are unique in guaranteeing our hulls and decks for life (learn more).

Shallow Draft and Precision Control

Our yachts are powered by water jets for a reason. Jet propulsion provides unrivaled precision handling with just the slightest touch. Jets are considered the best possible mechanical configuration for joystick applications because changing thrust direction on a jet is accomplished by simply changing the direction of water flow. Commercial and military boats that rely on continuous maneuverability select jets for this reason. The US Navy’s newly designed 43-foot PB-X and 85-foot Mark VI patrol boats are each powered by water jets for inshore maneuverability in unknown waters.

Without any appendages below the waterline, our yachts can safely maneuver in very shallow areas or in water with excessive debris such as lobster pots. Jets also become significantly more efficient than propeller-driven boats at speeds above 25-30 knots since there are no appendages below the waterline. The drag of propellers, pods and rudders rises exponentially above these speeds. Without these appendages, jets can operate at speeds above 25-30 knots with less drag and fuel consumption.

Our research and development continues to drive innovation. JetStick 3 now brings military grade GPS hardware and digital processing to a completely redesigned driving experience. Innovations found only on a Hinckley such as Heading Hold and Dynamic Steering allow the boat to understand your intended course and let you carve turns with ease.

Built Just For You, Cared For Entirely By Us

We start building your boat after you purchase it. It’s built just for you, to your specifications. Half the fun is working directly with our team to specify the engine package, teak options, electronics, canvas and cushions. Once your yacht is delivered to you, we provide three full days of hands-on training so you are fully confident in how to operate each and every system on board.

Building and owning a Hinckley is an unparalleled experienced. Hinckley is unique in owning and operating 10 world-class YachtCare Centers up and down the east coast. Our YachtCare program combines this unrivaled infrastructure with a new mobile service team to deliver an ownership experience like none other. Only Hinckley brings all of this together for an on-the-water experience with family and friends that is uniquely yours.